Peerprint chooses MGI

Digital Enobling - Peerprint, Israel's leading wine label printer, chooses MGI

Although the first wines produced in Israel date back to biblical times, the development of Israeli viticulture dates back to the end of the 19th century, when Baron Edmond de Rothschild decided to develop a local wine industry in 1882.

Today, the wine sector is particularly dynamic, with 250 wineries exporting to the whole world, very diverse wines, from 5 wine regions with very marked characters.

Founded in 1942, Peerprint has specialized in the wine label market from the beginning, with Carmel Winery (Rothschild) as its very first client, expanding over the years in parallel with the growth of local production. A family business run by Adi Levy (3e generation) and employing nearly 50 employees, Peerprint implements a strategy of One Stop ShopThe aim of the company is to offer producers all the skills they may need to help them promote their wines at the point of sale.

"Wine producers, whether they belong to groups or are independent, like cooperatives, have to constantly juggle production, marketing and sales of their wines, which is not always easy. Their activity depends on weather conditions, and they are subject to competition that is all the more intense because it is international", explains Adi Levy.

"In this context, our strategy is to make it easier for them to promote their wines, by offering them a complete service: Peerprint thus brings together a design agency and a packaging studio, and produces both dry labels and self-adhesive labels, cardboard boxes, displays and point-of-sale advertising, essential for promoting bottles in stores."

On the printing side, Peerprint has two HP 6800 digital presses and a Komori H-UV 75 x 105 cm sheet-fed press, while its finishing workshop uses traditional equipment - embossing, hot foil stamping, silk-screening - through 4 finishing lines GM, ABG and Prati... Equipment that was enriched, last September, with a digital roll-to-roll finishing press from the French manufacturer MGI Digital Technology, the JETvarnish 3D Web.

For Adi Levy, this investment had become essential: "We have been following the developments of the JETvarnish 3D Web from the beginning, and what we saw at LabelExpo 2017 really appealed to us. Our goal was to maintain our industry leadership, and digital finishing was a major comparative advantage for us.

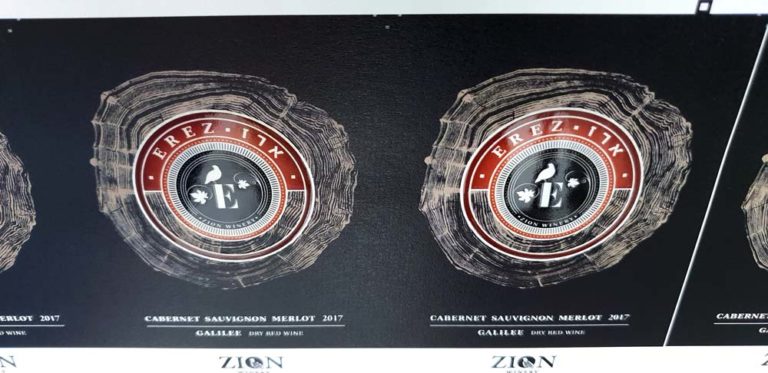

In June 2018 we confirmed the order, and received the JETvarnish 3D Web in September of the same year." In a commoditized market, Peerprint wanted to differentiate itself, offering new services to its customers, thanks to the 100% digital UV coating and hot foil stamping process, flat or embossed, of the JETvarnish 3D Web.

"The JETvarnish 3D Web allows us to offer things we couldn't before," explains Adi Levy. "Flat or embossed varnishes, embossing effects or hot foil stamping, on short and medium runs. The average print run to date on the JETvarnish is 15,000 labels, with a minimum of 200 - labels produced for an event - and a maximum of 50,000. It goes without saying that the implementation of the versioning campaign should enable us to go even further in the coming months".

While the quality of the finishing offered by MGI's JETvarnish 3D Web appealed to Peerprint - notably the consistency of the varnish application, whether flat or raised, and the finesse of the gilding - its durability was a major point for the Israeli printer: "During the JETvarnish purchasing process," explains Adi Levy, "one of the things that really impressed us was the durability of the MGI coating, given that bottles can collide with each other in cartons during transport. We were fully satisfied with the tests we carried out, which removed the last question we had before signing!"

Operational for a few months, the JETvarnish 3D Web from Peerprint has quickly found its place, whose high-tech features are a perfect match for the two HP 6800 digital presses.

In conclusion, Adi Levy comments: "The commissioning of the JETvarnish 3D Web went perfectly, and we can only praise the attentiveness, availability and professionalism of the MGI teams. It's important for us to be able to count on our suppliers on a daily basis, just as our own customers can count on us."