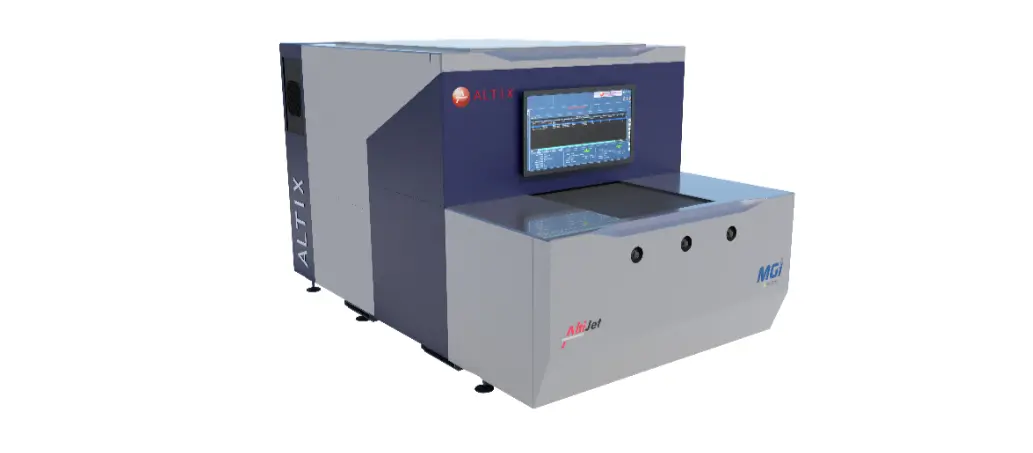

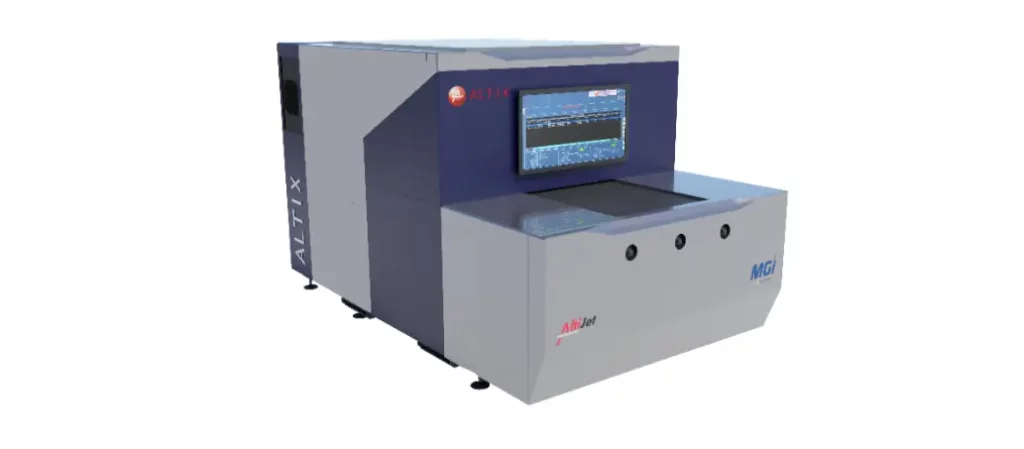

MGI Digital Technology - Altix partnership: First industrial inkjet machine for the printed circuit board market

Paris, November 13, 2023 - At the opening of the Productronica international trade fair in Munich, MGI Digital Technology and Altix announce a strategic technological partnership, and the launch of the AltiJet, an industrial inkjet production press for the printed circuit board market. This digital press, designed to apply Solder Mask and Etch Resist, is a genuine breakthrough innovation in a market largely dominated by conventional processes.

A fast-growing market

Valued at $82 billion, the printed circuit board production market is growing by almost 5% per year, and is expected to continue to do so over the next 10 years, reaching $140 billion in 2032. While Asia accounts for 80% of global production, Europe and the United States account for 5 and 3% respectively, a figure that is set to grow strongly in the years ahead, thanks to the resilience and relocation policies currently underway.

Printed circuit boards: the transition to digital inkjet

Printed circuit board production is a complex industrial process, involving numerous manufacturing stages and using technologies that have remained virtually unchanged over the last few years.

The solution developed by MGI and Altix considerably simplifies this process. The benefits for customers are manifold: shorter cycle times, savings in labor and energy, and significant reductions in chemical consumption and pollutant emissions.

Altix brings its expertise in printed circuit boards, and MGI its expertise in inkjet print engines and consumables for printed electronics. With this solution, the PCB industry will be able to begin its transition to digital, following the example set by the graphic arts and printing industries some twenty years ago.

MGI Digital Technology and Altix: strong industrial and strategic synergies

The partnership announced between MGI Digital Technology and Altix, initiated two years ago now, was a natural fit for Edmond Abergel, President of MGI Digital Technology: "Since 1982, MGI has developed by offering the printing and packaging market successive breakthrough innovations, with 100% digital production technologies. The culmination of this approach is the AlphaJET, the very first 5.0 digital 100% printing plant on the market. When we looked at related markets where our know-how in supporting industrial digital transition could be immediately applied, printed circuit board production immediately stood out. The meeting with Altix, a major French player in the PCB market, was a natural one, and the very similar DNAs of our two companies immediately led us to envisage joint developments".

This cultural and industrial complementarity is unique on the market, as Jérôme Van Straaten, CEO of Altix, explains: "Between Altix's 30 years of perfect knowledge of the PCB market and the excellence of its software and hardware equipment sold worldwide, and MGI's expertise in industrial inkjet printing solutions and related consumables, there is total synergy between our two companies. In this respect, the joint development of the AltiJet, our very first solder Mask and Etch Resist digital inkjet press, unique in its concept and unveiled at Productronica, is the best symbol".

AltiJet: versatility, cost reduction and environment

The launch of the AltiJet meets a strong need in the PCB market for simplification, reactivity and a reduction in carbon footprint, continues Jérôme Van Straaten: "AltiJet reduces the number of steps required to apply the Solder Mask from 50 to 60%: processing time is halved, as is the number of personnel required. From an environmental point of view, the replacement of a conventional subtractive process based on solvents and multiple manipulations by an additive inkjet process greatly reduces environmental impact, with the total elimination of solvents and a sharp drop in energy consumption".

Figures corroborated by the Fuji Chimera Research Institute. According to the Japanese research institute, simply switching to inkjet for the Solder Maks deposition stage would result in very significant reductions in pollutant emissions each year: -20,000 tonnes of VOC (volatile organic compound) emissions, -22.5 million tonnes of aqueous pollutant emissions and -70% of production waste.

AltiJet: a 360° solution, unique on the market

The fruit of the combined expertise of MGI and Altix, the AltiJet stands out in the Solder Mask and Etch Resist digital printing solutions market thanks to its unique concept, explains Edmond Abergel: "Our dual industrial experience led us, right from the start of the project, to imagine a complete solution, developed entirely in-house. We are not an assembler, but a manufacturer, IT developer and chemist. The AltiJet combines high-precision mechanics (on the order of 1 micron), high-definition inkjet print engines developed in-house, proprietary IT interfaces, programs and rips, and an ink specifically developed in our Ile-de-France plant for this purpose. Mastery of these different elements was the sine qua non for developing a digital press that best met the expectations of the sector's manufacturers".

AltiJet: a complementary solution to existing Solder Mask and Etch Resist industrial equipment

The AltiJet is aimed at a particularly broad market of printed circuit board manufacturers, offering them an unprecedented level of reactivity and versatility.

The AltiJet can be used to produce prototypes in record time, as well as to launch short and medium runs on demand, with the greatest of ease. The AltiJet's digital technology not only cuts production costs significantly for manufacturers, but also enables them to capture new markets, as their customers can now have their products produced on demand, in the shortest possible time, to adapt to changes in their products.

The AltiJet's versatility and ease of use make it a perfect complement to the conventional solutions currently used for high-volume production: the same is true of the printing and packaging sectors.