JETvarnish 3D Evo

Discover the flagship of the JETvarnish product range in B1+ format

Description of the JETvarnish 3D Evo

The JETvarnish 3D Evo is designed for offset and digital printers who want a digital finishing solution for demanding production environments. It allows 2D/3D UV selective varnishing, embossing up to 200 µm and 100% digital gilding.

This equipment delivers a high added value and sensory dimension to all printed productions. It is also an adapted solution for prototyping and proofs at very competitive costs.

JETvarnish 3D Evo ensures a high level of productivity up to 4,200 B2 ISO sheets per hour (70.7 x 50 cm). Its 8-positions format (up to 75×120 cm) allows it to respond favorably to the specificities of the packaging markets.

This solution has a revolutionary system with an artificial intelligence driven scanner - AIS© Artificial Intelligence SmartScanner. The whole system minimizes the time spent on makeready, controls and automatically corrects the production in real time for each sheet.

Technical characteristics of the JETvarnish 3D Evo

General characteristics

Formats

- Min : 42 x 29,7cm (width x length)

- Max : 75 x 120cm

Sheet weight

- Min: 135g/m² (or 150 µm) before printing and lamination

- Max: up to 600g/m².

Compatible with solid board

Substrates

- Direct application of the 3D coating on most of the(1) matt or glossy coated surfaces, with or without acrylic varnish, coated paper, plastic, PVC and other closed synthetic materials

- Direct application of the 3D coating on some(1) digital toners (e.g. MGI Meteor)

UV selective inkjet

General

- UV inkjet developed by MGI

- Drop-on-Demand (DoD) technology

- Piezo heads. Single pass printing

- Modular and scalable printing architecture

Varnish thickness

- Depending on the file and substrate used, from 3 microns(1) equivalent to a traditional selective varnish, up to 232µm(1) for a 3D touch effect.

Production speed

- The default sheet size is B2 ISO unless otherwise specified

- Up to 3,123(2) B2 sheets per hour for all models.

- Up to $4200(2) (3) B2 sheets per hour in the direction of the width 75cm

- Up to 2,8002) (3) B1 sheets by the hour

Tracking

- Motorized grinding feed table

- Automatic tracking via SmartScanner AIS as standard for full sheet scanning in real time

- Tolerance ± 200 microns

Printing width

- 54 cm (standard)

- 73 cm(4) according to the chosen configuration.

Digital hot stamping

General

- Optional digital hot stamping module

- The default sheet size is B2 ISO

- Production speed up to 2,300 B2 sheets(2) (3)

(lengthwise) per hour (or 25m/min) - Films - film consumption optimization system

Stamping coils

- Maximum roll diameter and length: ± 30cm and from 400 to 2000 meters of film. Up to 3 film reels can be loaded simultaneously with widths > 10cm

- 2 chucks available: 1 inch standard and 3 inches.

- Maximum area

- The useful surface of gilding can not exceed 73x118cm(3)

Embossing

- 2D and 3D tactile effects

- The metallized films can be covered with a layer of varnish for protection or aesthetic reinforcement

- the speed varies according to the parameters used

Dry air

- Requires 6 bar and 24 m supply3/hour (dry air and without oil)

Other options

CTS XL treatment

- Ceramic electrode technology

- In-line system designed to optimize coating adhesion on complex printed substrates

Variable data WTP

- Management and modification of files on the workstation

- Complete variable data (text, graphic, image) for selective varnishing and gilding areas.

- Integrated barcode reader (1D / 2D) Optional Raster Image Processor (RIP)

Dimensions

- Dimensions (L x W x H) & Weight Up to (L x D x H) 12.42 x 1.93 x 1.84m (Evo 75 all options)

- Necessary clearance: 1m on 3 sides and 2m at the recipe

- Up to ± 4,529 kg (Evo 75 all options)

(1). contact MGI to check the compatibility with your substrates / lamination / toner / acrylic varnishes

(2). The speed varies according to the parameters used

(3). with Evo 75 kit

(4). depending on the chosen configuration

Video presentation of the JETvarnish 3D Evo

Press articles on the JETvarnish 3D Evo

Tra i vantaggi elencati da Elcograf in favore del dispositivo di verniciatura digitale spot UV di MGI vi sono la drastica riduzione dei tempi di attesa, dal momento che è necessario solamente inviare il file in stampa e la macchina è pronta a produrre in pochi minuti, e la maggiore velocità di produzione rispetto alle altre soluzioni offerte dal mercato. A convincere, vi sono inoltre il modulo hotfoiling in linea, il sistema di messa a registro della verniciatura spot mediante scansione dell'immagine stampata (AIS Smart Scanner), which guarantees the centralization of the film on any type of work, even if it is printed digitally, the automatic pulverizing system of the inkjet testers and the efficient feeding and impiling system.

PrintPub – Elcograf Printing Company, Italy

Translation:

Among the advantages listed by ELCOGRAF in favor of MGI's JETvarnish 3D Evo 70×120 B1 are the drastic reduction in makeready time, since all you have to do is send the file to be printed and the press is ready for production in a matter of minutes, and the higher production speed compared with other solutions on the market. Other convincing features include the inline digital hot foil stamping module, and the on-the-fly varnish setting, controlled by the AIS scanner with artificial intelligence, guaranteeing perfect register throughout the print run. Finally, the printer emphasizes the efficiency of the automatic inkjet head cleaning system, and the practicality of the JETvarnish 3D Evo's margins and recipe, taken directly from the offset world.

Adam Carnell, managing director of Route 1's parent company Bluetree Group, said: "We were incredibly impressed with the capabilities of this machine and the opportunities it offers. With the MGI JETvarnish 3D Evo, we can introduce spot UV on a wider range of products, the option for low and high-build spot UV and, in due course, foiling. It's also highly automated, meaning we can set up multiple jobs one after the other, moving from long-run booklets to short-run business cards with ease. This was especially important to us because the demand for spot UV has increased in the past year. We needed equipment that would speed up production times without sacrificing quality. In fact, the MGI will improve our spot UV quality due to the registration and inline corona treatment."

Printing Week – Imprimerie Blutree Group, Great Britain

"Our company has garnered a large and loyal customer base over its 30 years of doing business in the province of Quebec. Having forged this newfound partnership with Konica Minolta and MGI, we look toward a creative, more productive future in the graphic communications industry. Thanks to this advanced technology in print servicing we are ready to expand our customer relationships and fulfill our clients' various needs," Le Groupe Stylex du Progrès CEO Massimo Papalia says."

Print Action – Stylex du Progrès Group Printing, Canada

"In just a few weeks, the 3D Evo has enabled us to move up a gear in packaging finishing," explains manager Avi Noima. "The B1 format allows us to gain in imposition and the pallet loader to load more sheets, and therefore reduce load breaks." In his opinion, MGI's JETvarnish 3D gives him a major advantage in the market, enabling him to offer "sensorial packaging", thanks to selective UV varnishes, hot foil stamping, flat or embossed, "both for short and medium runs and for large packaging versioning campaigns". The printer is delighted: "With one million sheets coated in six months, we've beaten our previous production records". He adds: "And we don't intend to stop there in the coming months!

Print Industry – Heret Printing, Israel

"The JETvarnish 3D Evolution is a one-of-a-kind machine," explained owner Tony Rouse, who serves as TEAM's President and CEO. "It takes an already printed piece and greatly enhances its appearance. During the last recession, many people dropped their print budgets and bought the cheapest printing available. Now it has come full circle and people are once again finding value in how a premium printed product can showcase their business. We are growing fast and now is the right time to add this machine."

[…]

"Adding the MGI JETvarnish 3D Evolution satisfies the requests we have received for more specialized thermography printing," concludes Rouse. "It runs at a greater speed, which is very important for our 22-inch by 40-inch work, and can handle more substrates. Adding this machine fits with our belief of investing in state-of-the-art equipment to give our customers what they need. By doing so, I know we will continue on our path for greater success."

Graphic Display World – Team Printing, USA

"Заказчики активно интересуются разными видами лакирования и тиснения фольгой, а также возможностью разделить тираж на несколько частей и каждую из них изготовить со своим вариантом отделки - это помогает им выделиться на рынке и увеличить продажи. Оборудование MGI, использующее струйную технологию для лакирования и цифровое тиснение фольгой, позволяет нам полностью удовлетворять подобные запросы."

[…]

"Для развития выпуска премиальной упаковки компания FineArtPrint положилась на Konica Minolta и технологию MGI, установив в начале пандемии младшую модель MGI Jet Varnish 3DS формата В3. Для клиента было важно понять, поможет ли она привлечь новых заказчиков, а также насколько стабильно будет работать бизнес в целом. Спустя всего 14 месяцев он нашел новые точки роста на рынке премиальной упаковки и, освоив технологию, увидел возможности для дальнейшего развития, для чего ему потребовалась более производительная машина большего формата."

PrintDaily.ru – Fine Art Print, Russia

Translation:

“Our print shop's customers are actively interested in different types of varnish and gilding, as well as in the possibility of splitting print runs to serialize them with a different finish. This enables them to stand out in the market and increase sales. MGI's JETvarnish 3D EVO, which uses inkjet technology for digital varnishing and gilding, enables us to fully meet these demands."

[...]

"FineArtPrint relied on MGI technology, marketed by Konica Minolta, to develop its high-end packaging production, initially installing the MGI JETvarnish 3DS in B3 format at the very start of the pandemic, before replacing it with a JETvarnish 3D EVO. It was important for the Russian printer to see if this would help attract new customers, while ensuring stability in overall business. After just 14 months, business growth in the high-end packaging market and mastery of the pnt technology led the company's management to opt for a larger-format machine.

A huge advocate for MGI embellishments, Post Press educates its clients on what it can do for them on a job-by-job basis, such as using texture and depth to enhance their prints.

[…]

"The MGI JETvarnish 3D Evo combines services I knew our customers could and would use, and we believe it sets us apart from other traditional business shackles," said Andy Humble, President and Owner of Post Press Specialties he said. "Customers have been very impressed with the details that can be obtained with the foil and also with how well it is registered in their prints."

[…]

While providing dynamic performance for the most demanding applications, the MGI Jetvarnish 3D Evolution (Evo) 75 delivers added value and sensory dimensional texture to printed output.

Missouri News – Printing Post Press, USA

Punta di diamante del reparto è la nuova MGI JETvarnish 3D Evo con sistemaiFoil, fornita da Konica Minolta e a breveupgradata nel formato 75×120, per far fronte alle richieste di clienti che necessitano la nobilitazione su grandi formati.

"La scelta di installare la nuova MGI ci ha consentito di fare la differentia. - spiega Pasquale Paciocco - Si tratta della seconda macchina in questa configurazione installata in Italia e la prima nel centro-sud. We consider the JETvarnish a true technological asset for digital branding both in the packaging and commercial printing sectors.

Printpub – Printing Pomigliano d'Arco, Italy

Translation:

The flagship of the finishing department at Italian printer Pomigliano d'Arco is the new MGI JETvarnish 3D EVO, acquired from Konica-Minolta Italia. This 75×120 digital finishing press will enable the company to meet the demands of customers looking for large-format finishing.

"The decision to install the new MGI JETvarnish 3D EVO enabled us to make the difference," explains Pasquale Paciocco. "This is the second machine of this configuration installed in Italy, and the very first in the centre-south. We see the JETvarnish as a real technological jewel for digital finishing, both for packaging and commercial printing."

This system is revolutionary and represents a technological leap forward compared with all other systems on the market," says Dann Ramstein. It's the only system in the world that specifically corrects each page for its own faults. It requires no register marks to process the sheets." This highly advanced technology makes a major contribution to the operator by relieving him of the tasks of makeready and quality monitoring. "Productivity and the highest register quality throughout production are the two major beneficiaries of this major innovation." Flat selective varnish, relief varnish with 3D effects and variable data hot foil stamping are ICA's three new areas of expertise. "These are formidable growth levers that are highly differentiating" concludes Rémi Courand.

Print Industry – ICA Printing, France

Testimonials and achievements of our customers on the JETvarnish 3D Evo

PaperSpecs video with Sabine Lenz

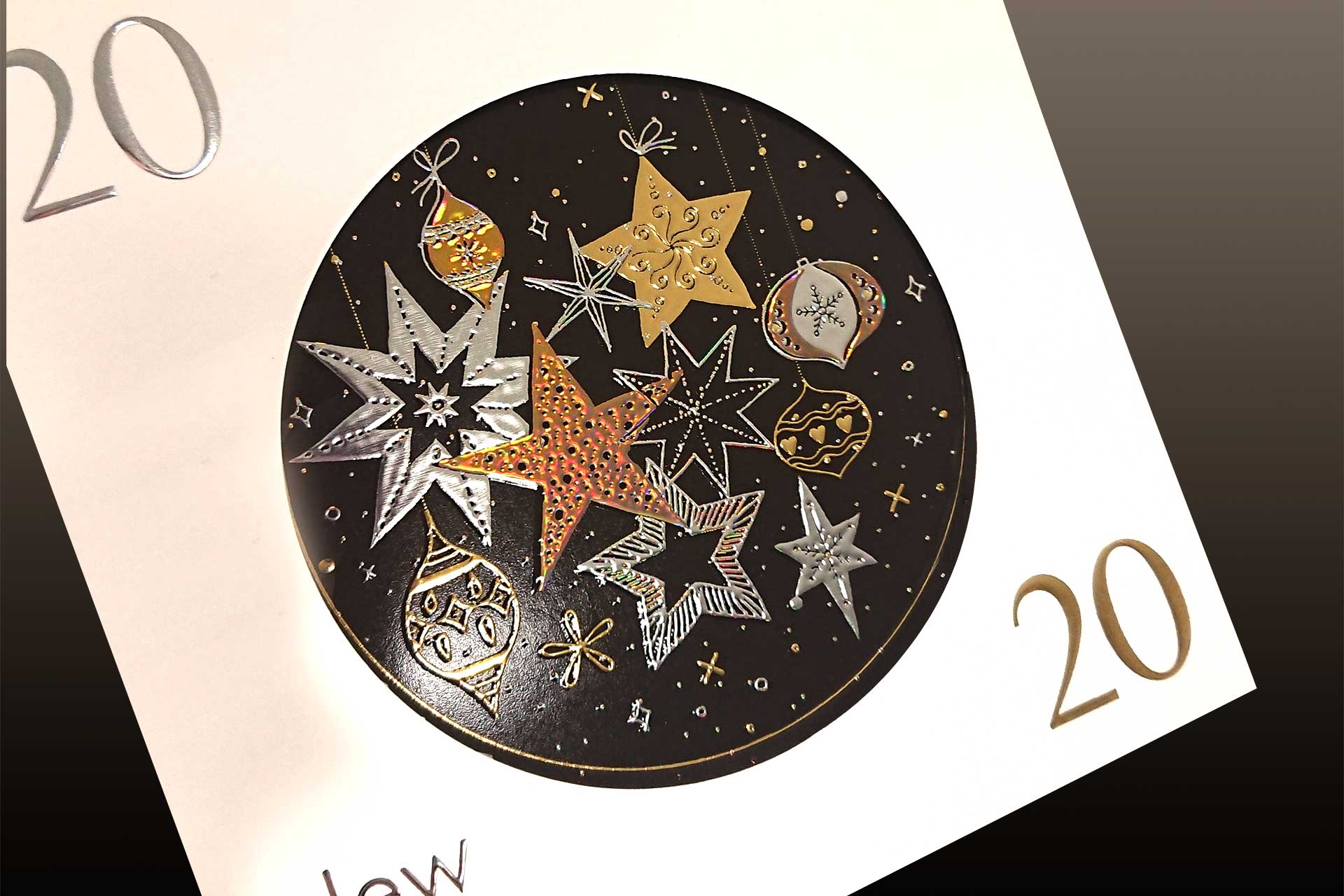

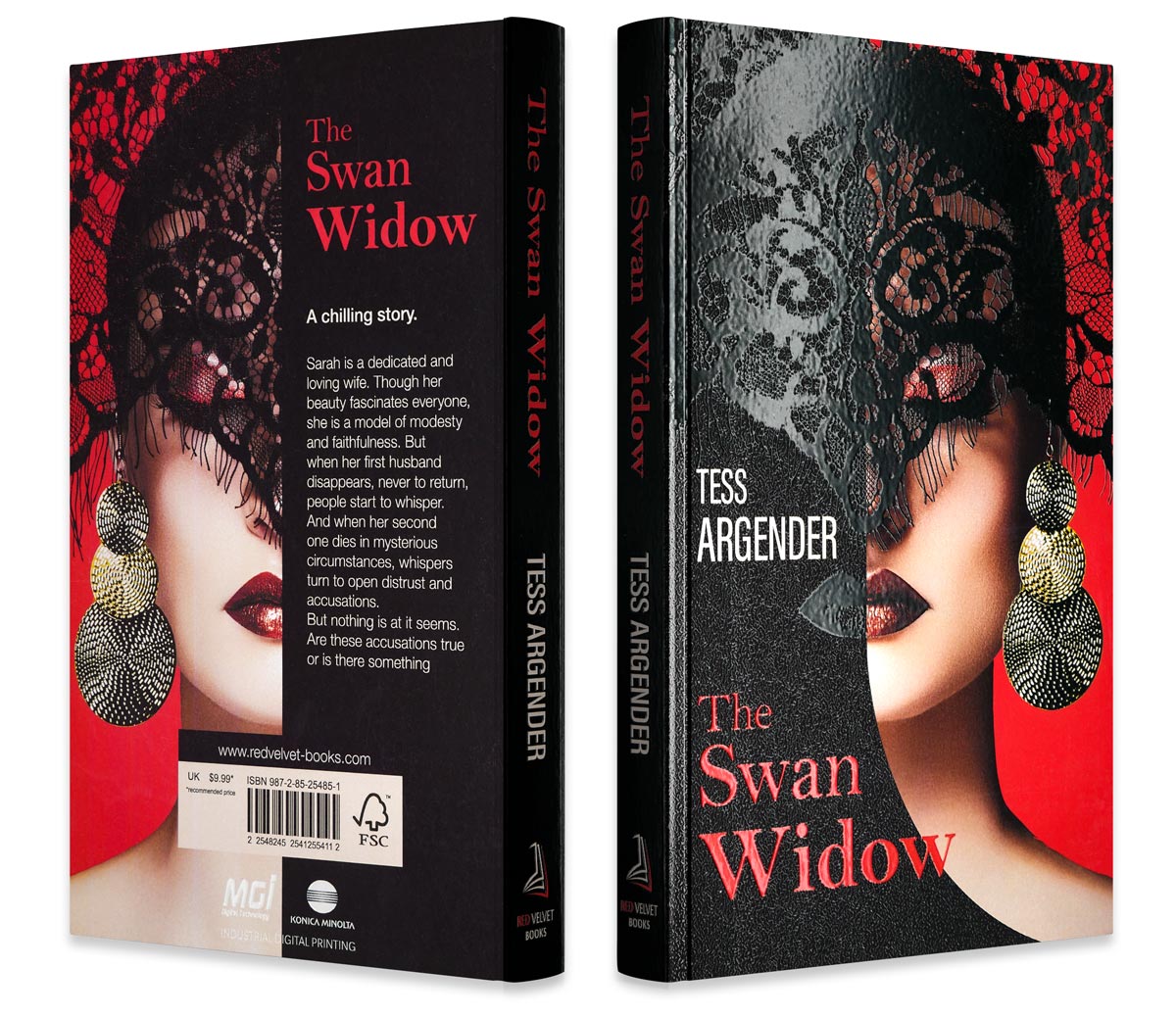

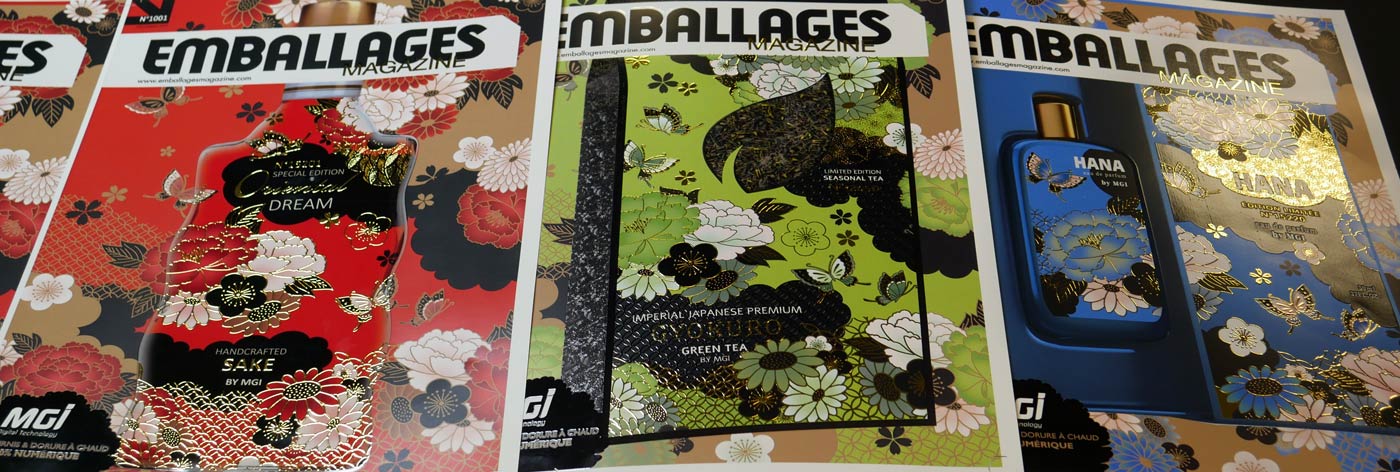

Design: Grafikmagazin (Tobias Holzmann)

Printing: Konica Minolta Germany / F&W Druck-und Mediencenter

Ennoblissement: MGI Digital Technology's JETvarnish Evo

Paper: MetsäBoard / Sappi North America / Berberich Papier