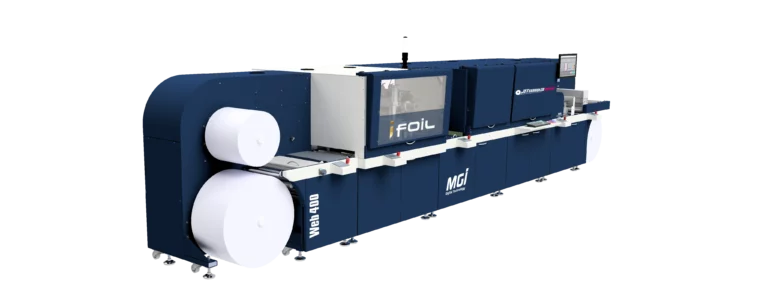

JETvarnish 3D Web

The very first digital reel-to-reel finishing press on the market

The JETvarnish 3D Web allows printers of labels, sleeves, flexible packaging or flexible cartons to apply a 100% digital finishing on rolls ranging from 100mm width to 420mm, on media previously printed in offset, flexo, digital, etc.

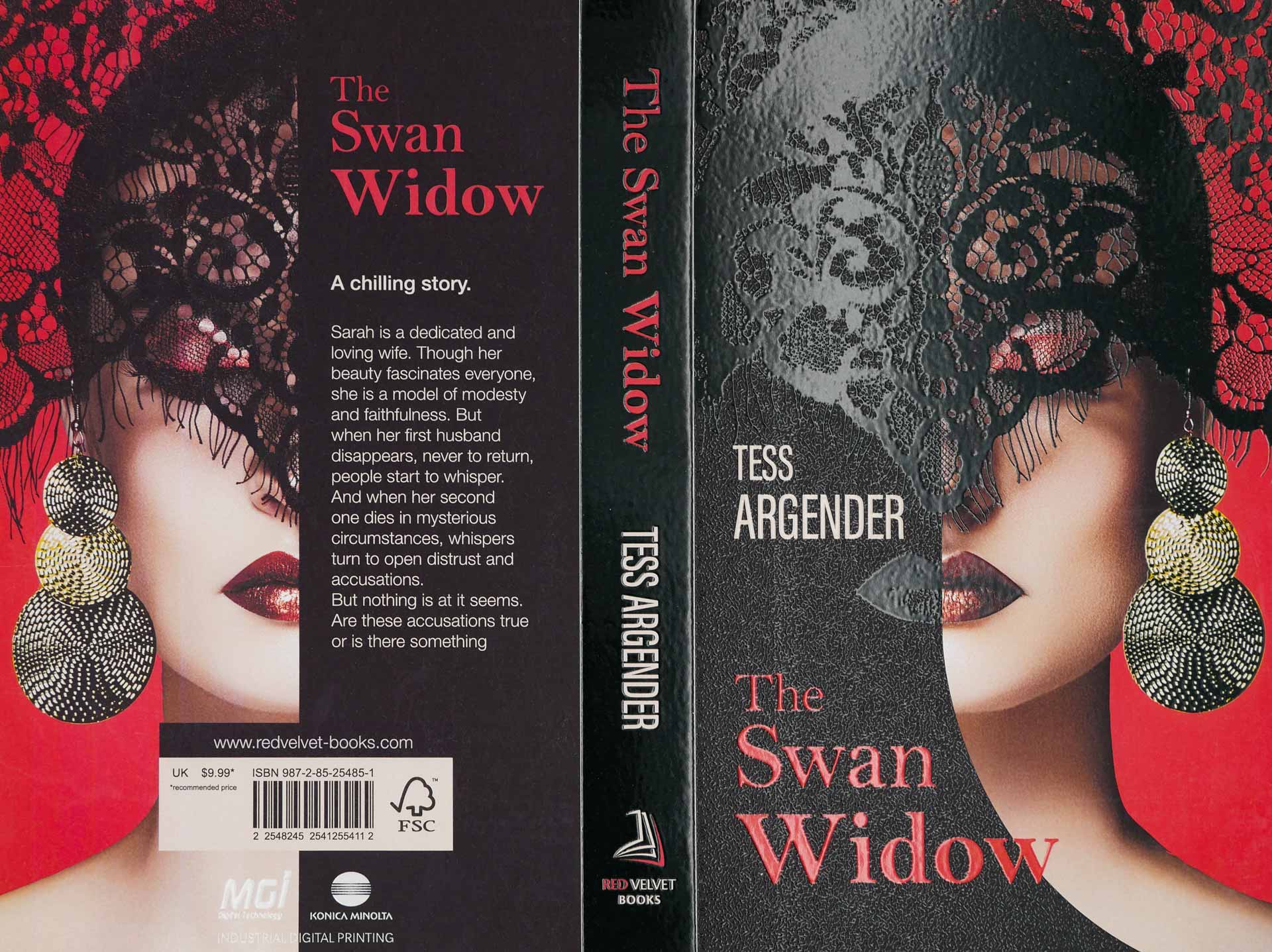

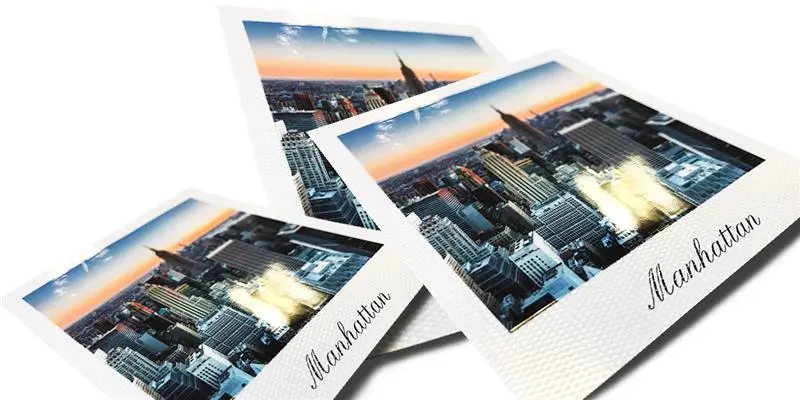

This equipment applies selective UV varnish and hot foil stamping, in 2D/3D, on all types of labels or light cardboard, using MGI inkjet technology. The selective UV varnish and the hot foil stamping bring a very strong added value and confer a sensory and tactile dimension which boosts the attractiveness of the products on the shop's shelf.

The 100% digital technology of the JETvarnish 3D Web allows to apply these coatings in fixed or variable data, making possible things that were not possible until now, such as different hot foil patterns or selective varnish on each label / sleeve or packaging coated!

On-the-fly registration, controlled by artificial intelligence (AIS Smartscanner), allows perfect registration of the varnish and the gilding, by adapting their application to the defects observed in real time on the printed roll. Traditional makeready times are virtually eliminated.

The implementation of JETvarnish 3D Web does not require any tooling, plate or cliché, and drastically reduces the costs of finishing, allowing a great flexibility of use, ranging from large mass production, to prototyping, through versioning.

General characteristics

Printing speed

Up to 42m/mn(1) (depending on the application)

Supported widths

- From 100mm to 420mm

- Useful printing width up to 405mm

Tracking

The JETvarnish 3D Web is equipped with a revolutionary on-the-fly registration system, controlled by Artificial Intelligence, the AIS SmartScanner, which scans each application and corrects the application of varnish and gilding, according to any deformation of the substrate. With this automated on-the-fly registration process, the operator is freed from time-consuming makeready

Flexo printing module

Integrated flexographic station to apply a surface treatment on all or part of the web. This station is mainly used to apply a UV primer before finishing. The module is delivered with a UV dryer. The module is delivered with an anilox roller. Additional anilox rolls are available as an option depending on the application.

Substrates

- From 50 to 400 microns (μm)(2)

- Coated, uncoated and textured paper, film or labels

- Adhesive labels

- White or transparent synthetics, PP, PE, POPP, PET

- Flexible cardboard

- Shrink film: PVC, PETG

Unwinder

- max. outer diameter 850 mm

- 76 mm (3 inch) pneumatic chuck

- weight capacity 120 kg max

Rewinder

Servo-driven rewinding unit:

- Max. outer diameter 850 mm

- 76 mm (3 inch) pneumatic chuck

- Max. supported weight 120 kg

UV selective varnish and embossing module

General

This station uses MGI inkjet technology for the production of UV selective varnish. A simple grayscale TIF file, designed by the prepress department, determines both the area to be coated and the different thicknesses of coating to be applied to each label. This 100% digital process eliminates screen printing screens.

Varnish and drying

- Varnish thicknesses: from 7(2) up to 232(2) μm (for flat (2D) or 3D effects).

- In-line drying: The module is equipped with a UV dryer and chill roll for optimal substrate temperature control. The drying cycle includes a roll advance and rewind function to perfectly dry each label and produce a perfect quality while running jobs without waste.

- High gloss varnish 99 GU.

Digital hot stamping module

General

The hot foil stamping module brings a very high added value to all your labels. A simple TIF file, designed by the prepress department, determines the surface that will receive the foil for each label. This 100% digital process eliminates clichés. This module can be disabled at any time.

Stamping coils

The hot stamping films are delivered in reels:

- Film from 100 to 420mm width,

- Two chucks available: 76mm (3 inches) and 25,4mm (1 inch)

- Length of 400 to 2,000 meters of gilding film.

- Up to 3 stamping reels on the same web.

Other options

Corona treatment

In-line system designed to optimize coating adhesion on complex printed substrates.

Cutting, slitting and trimming module

Complete semi-rotary slitting and rewinding module, with the possibility of adding an additional double rewinder, for an all-in-one solution: printing, finishing, slitting, rewinding and slitting.

Variable data WTP

- Management and modification of files on the workstation

- Complete variable data (text, graphic, image) for selective varnishing and gilding areas

- Integrated barcode reader (1D / 2D) Optional Raster Image Processor (RIP)

Dimensions

- Up to 11.85(3) x 1,58 x 1,81m

- Required clearances: 1 meter on all 4 sides

- Weight: ± 4.447kg

Extended Compatibility

Compatible with all web-to-web printing technologies: digital offset and flexographic presses. Compatibility list of printing presses:

- Narrow web printing presses

- Digital: Konica Minolta Accurio Label, HP Indigo WS4500, HP Indigo WS6800, Epson, Xeikon, EFI, Durst, etc.

- Offset: all manufacturers and technologies: UV, H2O or waterless

- Flexo: all manufacturers and technologies: UV or water based

(1) the speed varies according to the parameters used

(2) contact MGI to check the compatibility of your substrates

(3) depending on the chosen configuration