Drupa 2024 - MGI Digital Techonology brings Factory 5.0 to printing, packaging and self-adhesive labels

Drupa, which takes place from May 28 to June 7 in Düsseldorf, is an opportunity for the group to MGI Digital Technologyto highlight all the added value provided by theFactory 5.0 digital printing and finishing in a single pass, for packaging, publishing, web-to-print, commercial printing and self-adhesive label professionals.

On a 3000m2 stand located in the Hall 8B (8B - A40-1) the MGI-Konica Minolta Alliance has recreated real production workshops organized by business line, presenting the market's broadest offering in digital printing and finishing, from sheet-fed (from SRA3 to B1 via B2) to reel-to-reel.

These different workshops will print and finish real products in real time (packaging, publishing and web-to-print printed matter, self-adhesive labels, etc.), at the end of automated end-to-end workflows combining different types of equipment.

MGI Digital Technology will be exhibiting 5 equipment in Düsseldorf: AlphaJET, JETvarnish 3D EVO, JETvarnish 3D Web-400, Octopus Web and AccurioShine 3600 powerded by MGI, all connected and benefiting from predictive maintenance.

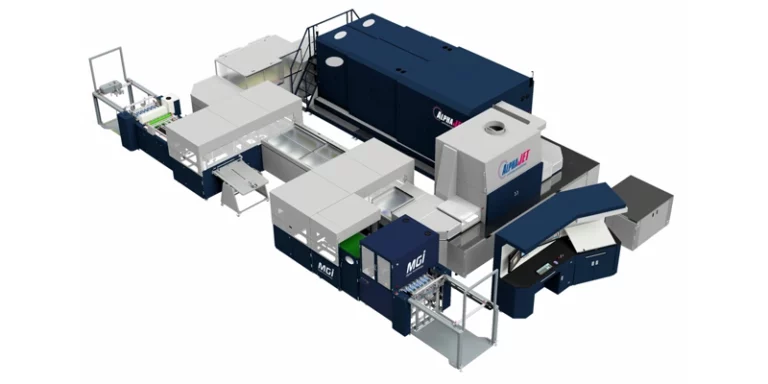

MGI AlphaJET - the 5.0 digital printing and finishing plant

The highlight of the MGI-Konica Minolta Alliance stand, the AlphaJet is one of the largest pieces of digital equipment on display at Drupa 2024, requiring almost 11 semi-trailers to transport it! L'AlphaJET is a printing plant 5.0100% digital, which performs nearly 4 operations in a single pass, on B1 and B2 sheets 1200 dpi four-color aqueous inkjet printing, coating OPV protective varnish replacing plastic lamination, varnish application UV selective andhot-dip gildingflat or raised.

On the DRUPA 2024MGI will be highlighting the very wide range of substrates already certified on theAlphaJETwith papermaking partners such as Fedrigoini, RDM, Westrock, Mandeure, Torraspapel, Eska....

MGI JETvarnish 3D EVO: total versatility of use B1-B2

The JETvarnish 3D EVO is THE market's benchmark sheet-fed digital finishing press in B1 and B2. It allows the removal of a UV selective varnish and hot foil stamping, flat or embossed, in fixed or variable data, on all types of paper, open or closed, with or without lamination. On the DrupaLa JETvarnish 3D EVO will be connected to a Konica Minolta automatic feeder, and will ennoble B2 printed matter from the KM1 digital inkjet press.

Alongside these B2 sheets, the JETvarnish will ennoble B1 offset printedto demonstrate its versatility of use in thecommercial printingfrom packagingpublishing and Web to Print.

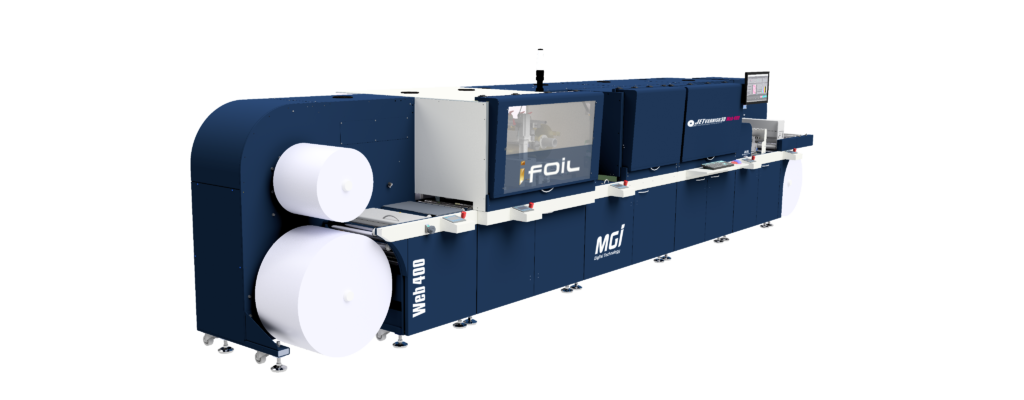

MGI JETvarnish 3D WEB 400: single pass UV selective varnish AND 100% digital hot foil stamping

On the occasion of the Drupa 2024MGI will be unveiling its second-generationdigital reel-to-reel finishingthe JETvarnish 3D Web-400 ! This new generation now allows UV selective varnish and hot foil stampingflat or raised, in fixed or variable datain a single passusing technology derived from theAlphaJET ! Equipped witha flexo groupa semi-rotary cutting and a double rewinderthe JETvarnish 3D Web-400 offers total versatility of use, for short, medium and long runs, on all types of substrates!

In Düsseldorf, the JETvarnish 3D Web-400 will ennoble reels previously printed on Konica Minolta AccurioLabel 400 and 230 presses, on natural or synthetic papersfrom UPM, but also on UPM Forest eco-sourced PP.

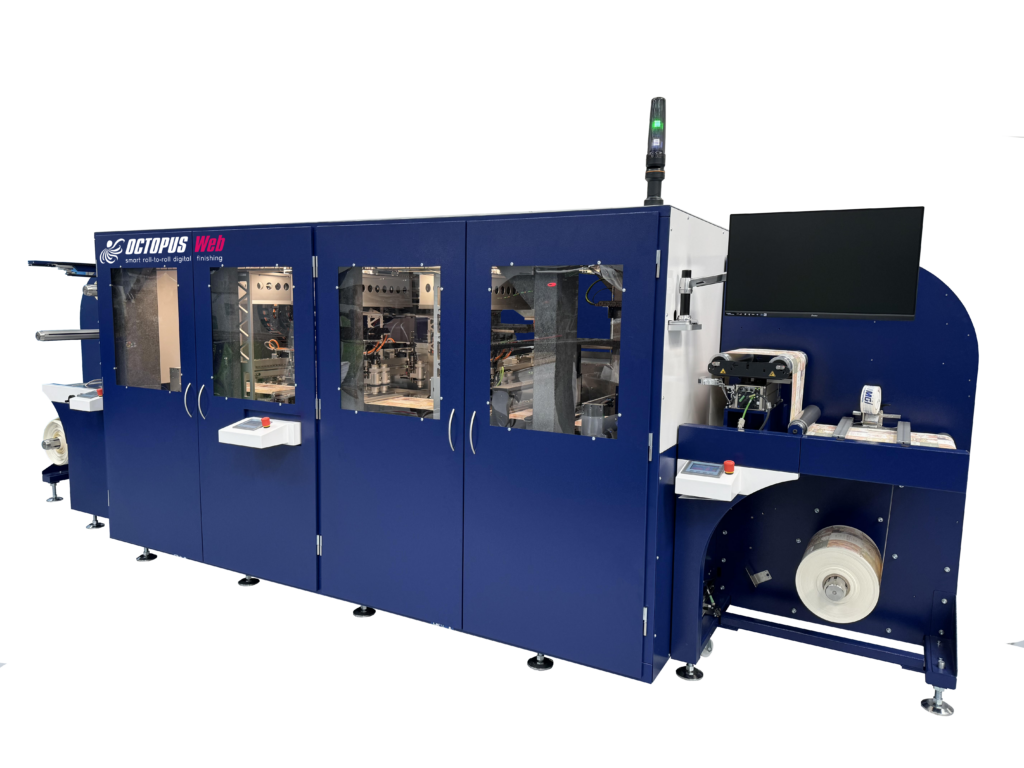

Octopus WEB: digital cutting.... that does away with lasers!

L'Octopus WEB presented at the show, is a genuine innovation in the field of digital reel-to-reel cutting. The cutting operation is carried out not by laser, but by 4-axis heads equipped with professional cutting blades! This technological choice reconciles the best of the traditional and the digital, and is compatible with all substrates. synthetics (PVC, PP), and cotton papers (without laser burn marks), for reduced power consumption. Thanks to theOctopusPDF to Cut becomes a reality, on all types of substrates, coated papers, uncoated and syntheticsat the highest level of quality.

One of a kindOctopus transforms the die-cutting operation into a new element of label finishing, thanks to versioning die-cutting, facilitating pack differentiation on the shelf. L'Octopus will be cutting live coils printed on AccurioLabel 400 and coated on MGI JETvarnish 3D Web-400.

Connected MGI equipment for immediate entry into Industry 5.0

Connected to a secure cloud through MGI ConnectMGI's equipment is an opportunity for printers to enter the world of printing. l'Industry 5.0 online submission of 3D and augmented-reality BàTs with customers, remote production monitoring, order archiving, real-time machine fleet monitoring, predictive maintenance, through our solutions MGI Approve and MGI Dashboard. These solutions help to reduce costs while offering improved quality of service, for greater industrial resilience.

The social network MGI JetforceLast but not least, we'll be putting the spotlight on the "MGI" community, which enables manufacturers equipped with MGI solutions to develop their networks and technical knowledge on a day-to-day basis, through forums, testimonials, reports and thematic meetings, so as to benefit from the community's know-how.

L'printing 5.0 MGI-Konica Minolta will be from May 28 to June 7on the Drupa in Düsseldorf, Hall 8B, Stand A40-1.

Digital, for greater respect for the environment

On the Drupathe MGI Digital Technology will highlight theeco-responsibility of its various technologies, with solutions using solvent-free varnishesand without single-use consumables (plates, screens, clichés). Removing waste and generating 30% in energy savings Compared with conventional equipment, MGI solutions are distinguished by certified de-inkable varnishes and hot stamping on certain substrates, according to the following process Ingede 11.