JETVARNISH 3D One

MGI offers the simplest and most affordable way to join the JETVARNISH family of digital finishing presses.

This family is rich of 7 models, in sheet to sheet or in reel to reel.

Description of the JETVARNISH 3D One

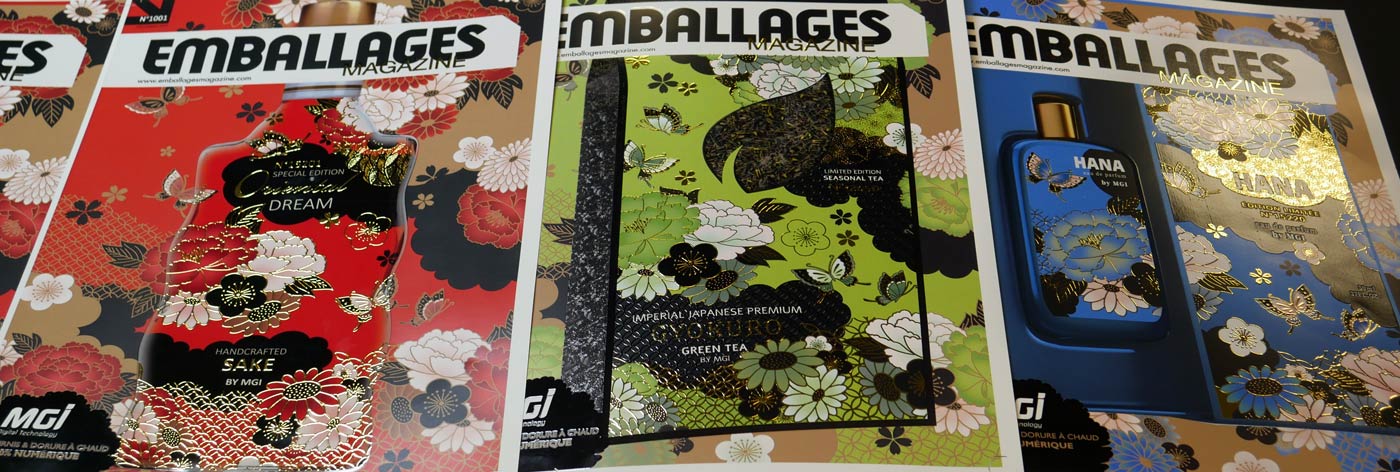

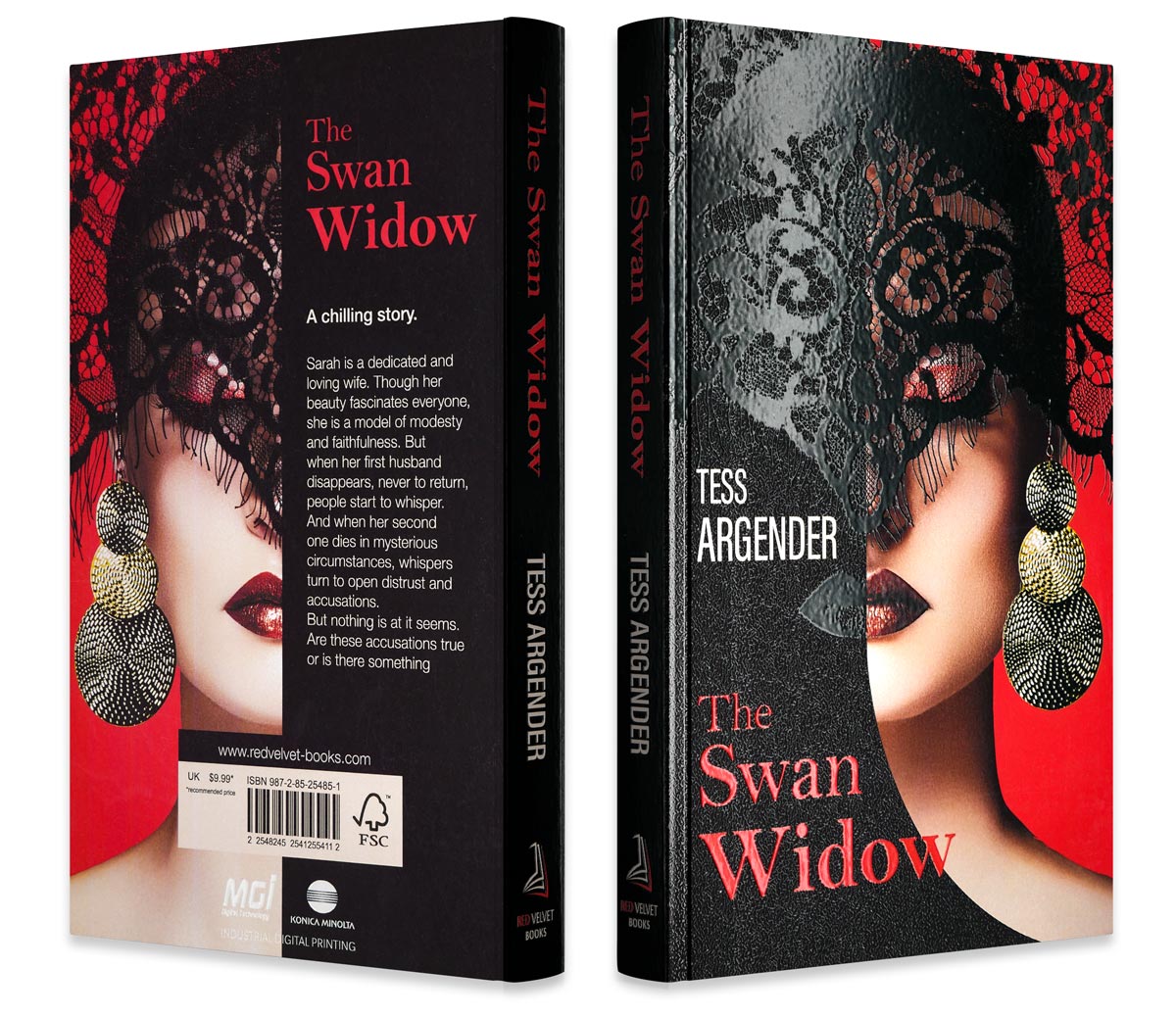

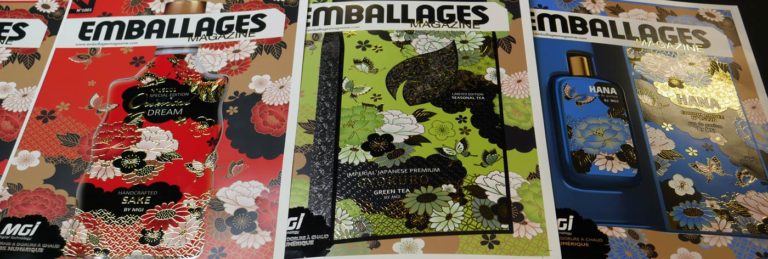

The JETVARNISH 3D Onemarketed by Konica Minolta under the name AccurioShine 3600is the ideal solution for any printer wishing to embark on digital embellishment. With its small footprint, it provides an in-house UV digital coater capable of high value-added production, from prototyping to mass production, without screens, chemical solvents, clichés or tooling.

The JETVARNISH 3D One uses only one type of coating to produce 2D or 3D tactile coatings, in fixed or variable data. Its automatic cleaning system of the inkjet heads allows to optimize its uptime with ease.

Versatile, the JETVARNISH 3D One allows the application of flat or raised varnish with tactile effect, on substrates as varied as paper, cardboard or plastic, from 135 to 450g, previously printed in digital (toner or inkjet), offset, screen or flexo printing.

As an option, the JETVARNISH 3D One / AccurioShine 3600 can be fitted with an iFOIL module for digital hot foil stamping, flat or raised, in fixed or variable data.

Easy to use, the JETVARNISH 3D One is controlled from an onboard screen, integrating file management, cost calculator and direct retouching of coating files. The AIS SmartScanner, an artificial intelligence-driven automatic registration system, guarantees perfect coating registration from the very first page, and automatically corrects the coating application in real time, according to any substrate deformation.

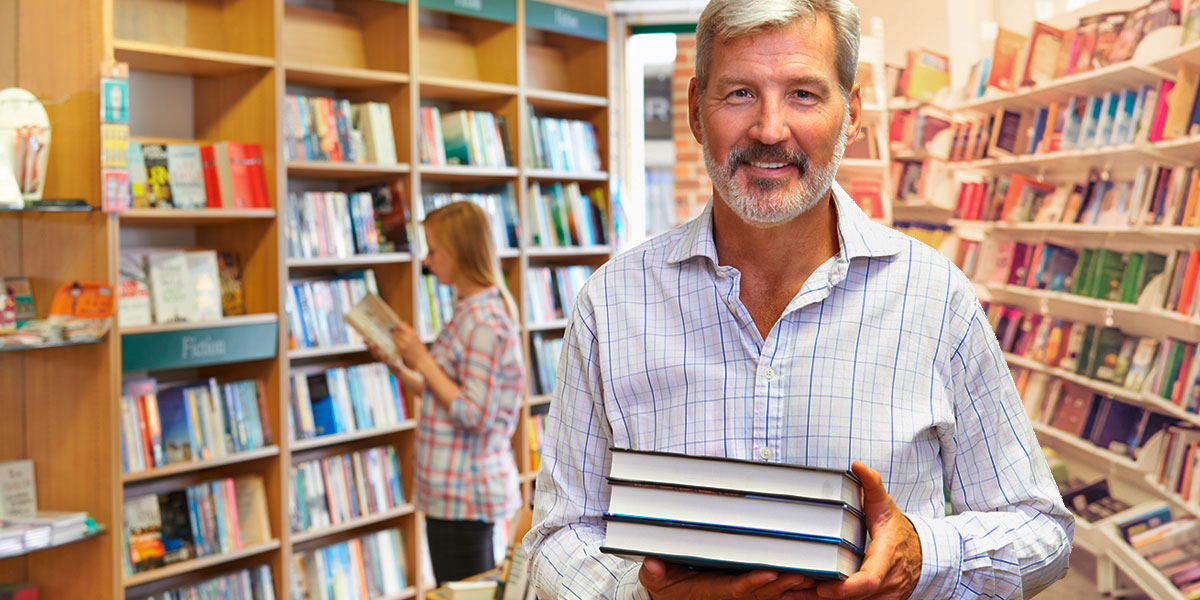

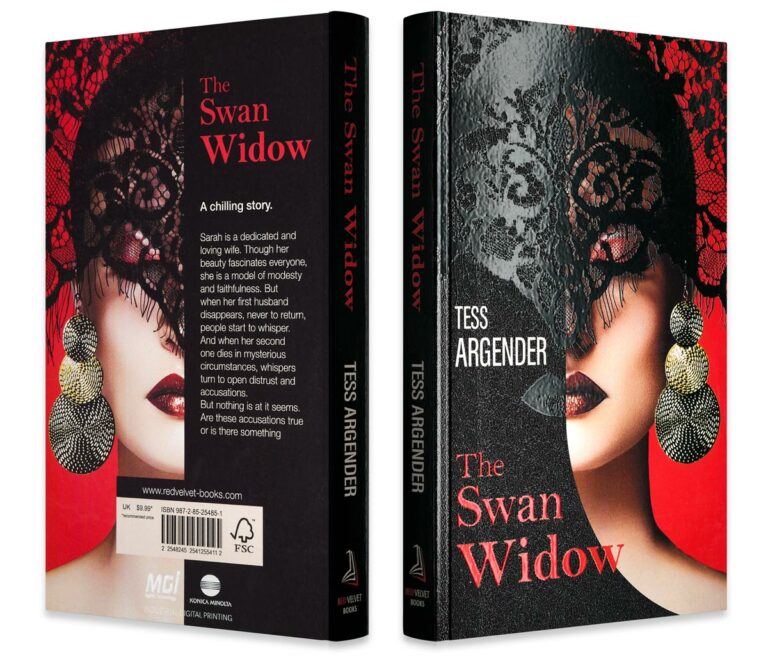

Agile, the JETVARNISH 3D One allows printers to differentiate themselves by offering to enrich printed materials with sensory and tactile effects on all types of documents: business cards, announcements, brochures, book covers, leaflets, labels, folding boxes...

With the JETVARNISH 3D One, it has never been easier to enter the market of UV selective varnishing, flat or embossed, while benefiting from the quality of the technologies and the service of the world leader in the sector.

General characteristics

Formats

- Min : 210 x 297mm

- Max : 364 x 750mm

Margin

High capacity, up to 28cm or 2,200 sheets in 135 gsm

Paper feed by suction and belt

Recipe

- Capacity: 1,250 sheets in 135 g/m2

- Overflow sensor

Paper transport

- 100% flat track

- Vacuum system

- Automatic double sheet detection

Maintenance and video maintenance

- Automatic head cleaning and wiping

- Less than 10 minutes of daily maintenance

- Numerous automated procedures

- Cold start < 10 minutes

- Remote video support with webcam (broadband Internet connection required)

Substrates

- Compatible with most matte or glossy laminated surfaces, with or without acrylic varnish, coated paper, plastic, PVC and other closed surfaces (1)

- Direct printing on most digital prints without lamination or surface treatment (1)

Substrate thicknesses

- Motorized height adjustment of the heads

- Min: 135g/m² or 150 µm before printing and lamination

- Max: up to 450g/m² or 450 µm with printing and lamination

Front End System

- Control via a screen

- Many features:

Ethernet 10/100/1000 BT connection in RJ 45

Production cost calculator, image editor, queue and reprint management, print head, speed and time settings, etc. - Parameters and technical data of the equipment accessible via PLC

- Possibility to modify varnish files on machine, without DTP (Image Editor)

UV selective inkjet

General

- UV inkjet developed by MGI

- Drop-on-Demand (DoD) technology

- Piezo heads. Single pass printing

- Modular and scalable printing architecture

Production speed

- Up to 3500 A4/hour in 21µm

Useful printing width

352mm

UV varnish and autonomy

The JETVARNISH 3D One is delivered with a 10 liter can of varnish. Canister change during production, without machine stop

Varnish thickness

- Depending on the file and the substrate used, the thickness of the coating can vary from 21(1) microns (μm), equivalent to a traditional selective varnish, up to 116(1) μm for a 3D touch effect

- The minimum thickness on toner is 30/35µm for optimal print quality

Tracking

- Automatic tracking via AIS SmartScanner as standard for full sheet scanning in real time.

- Tolerance ± 200 microns

In-line UV curing

- With ozone-free LED technology

- Ability to handle or finish coated sheets - immediate

Other options

Coaxial lamp

SmartScanner AIS coaxial lamp for metallized papers

Variable data

- Automatic PDF converter using PC-C1

- Camera for automatic reading of pre-printed barcodes

Dimensions

- Dimensions (W x D x H) & weight: from 4.02 x 1.2 x 1.80m

- Necessary clearance: 1m all around the press

- Up to ± 1068kg

Default sheet sizes are ISO standard unless otherwise noted. All speeds are nominal.

(1) contact MGI to check compatibility with your substrates / lamination / toner / acrylic varnishes